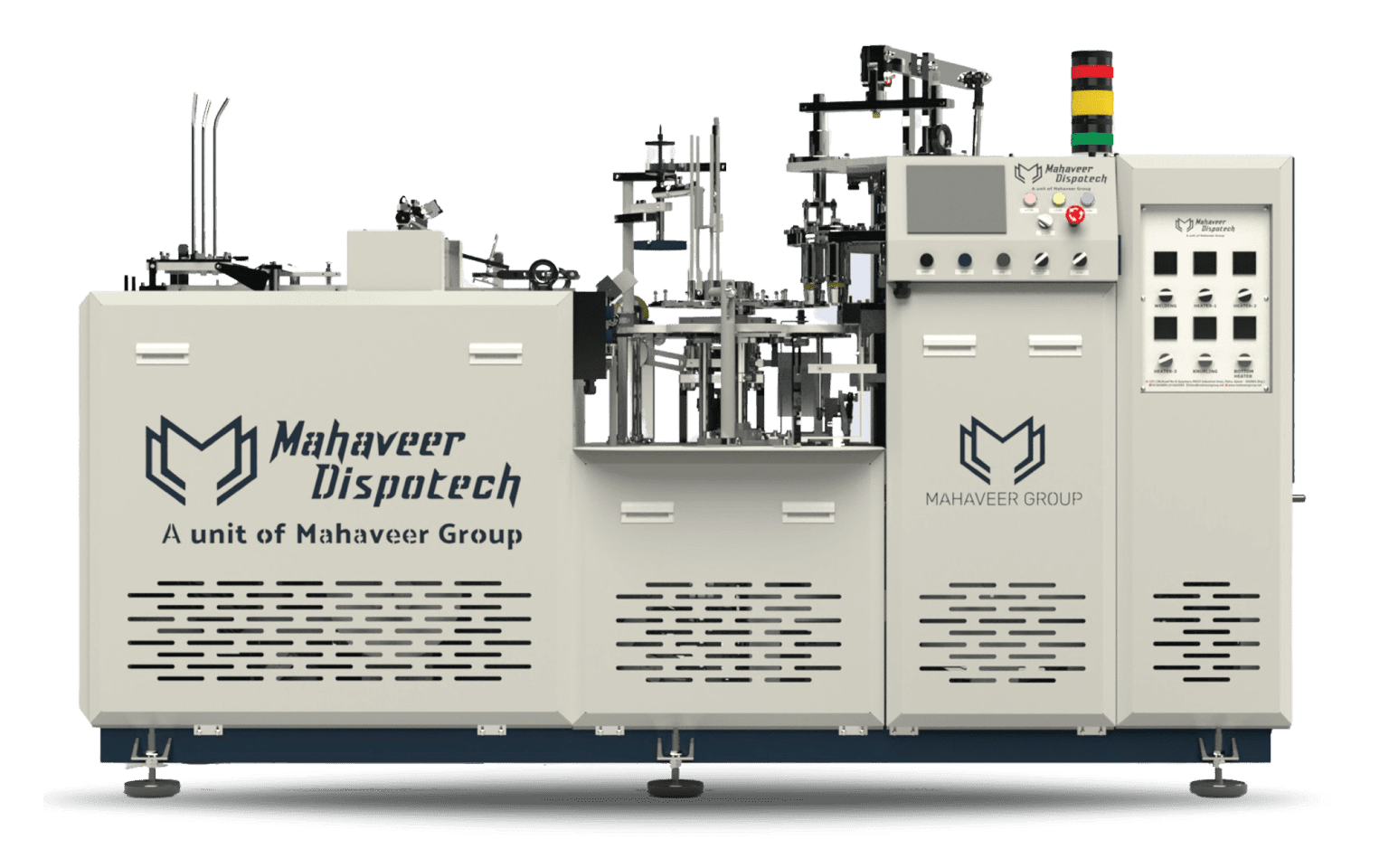

MG900Smart

High Speed Paper Cup Making Machines MG900Smart

The MG900Smart isn’t just a machine, it’s an environmental champion that automates the entire paper cup production process.

This Eco-friendly marvel handles everything from feeding the paper to shaping the final cup, including:

- Precise Feeding: Ensures consistent material usage.

- Airtight Sealing: Creates a strong, leak-proof wall.

- Efficient Oiling: Smooths the cup for a flawless finish.

- Knurled Bottom: Adds stability and grip.

- Controlled Heating: Forms the cup perfectly.

- Accurate Rolling: Creates a clean, even rim.

- Flawless Rounding: Delivers a comfortable drinking experience.

- Reliable Tripping: Separates cups cleanly and efficiently.

But that’s not all! The MG900Smart lets you customize every cup dimension, from volume to depth, diameter to height. You can create the perfect cup for any need.

Upgrade your paper cup production with the MG900Smart – the future is automated, efficient, and eco-friendly.

Technology Partners

Our Technology Partners provide cutting-edge solutions that empower us to deliver innovative and reliable services to our clients, ensuring the highest levels of performance and security.